Detailed Product Description

| Product Name: | Eliquid Filling Machine | Dimension(L*W*H): | 2000*1600*1600mm |

|---|---|---|---|

| Weight: | 500kg | Name: | Eliquid Filling Machine |

| Filling Nozzle Number: | 2 | Filling Range: | 5-50ml |

| Capacity: | 15-40 Bottles/min | Pump Type: | Peristaltic Pump |

| High Light: | perfume bottle filling machine, perfume packaging machine | ||

Customized NP-Y2 Automatic 10ml 15ml 30ml Nail Polish Bottle Filling Machine

Product Description

Main character of eliquid, small liquid bottle filling machine

1. PLC control

2. No bottle, no filling

3. CE certificate+GMP standard

4. Full stainless steel machine

5. Peristaltic pump precise filling

This Production line including below machines

1) Plastic Bottle unscrambling machine

2) Bottle filling ,dropping and capping machine

3) Automatic lableing machine

4) Bottle collecting

Application

This production line is mainly used for electronic cigarette liquid, eye drop, nail polish, eye shadow, essential oil and so on products fully automatic filling production.

Performance Feature

1. The working process: bottle unscrambling-- bottle washing (optional)-- filling-- adding dropper/(adding plug -- adding cap)-- screw capping--self adhesive labeling/shrink sleeve labeling (optional) -- ribbon printing/inkjet printing (optional)-- cartoning (optional).

2. This machine adopts mechanical arm to screw caps, equipped with automatic sliding device, to prevent the cap damaging.

3. Peristaltic pump or piston pump filling, measuring precision, convenient manipulation.

4. Filling system has function of suck back, prevent the liquid leak through.

5. Color touch screen display, PLC control system, no bottle no filling (only peristaltic pump)/ no adding plug/ no capping.

6. The whole line is compact, high speed, high degree of automation, save the manpower cost.

7. Main electrical elements adopts foreign well-known brand.

8. Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

Machine Usage and Features

This machine is mainly suitable for automatic filling, stoppering and screw capping of electronic cigarette liquid, eye drops, nail polish,

eye shadow, essential oil, with filling volume less then 50 ml.

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage.

2. Peristaltic pump filling, measuring precision, convenient manipulation.

3. Filling system has function of suck back, avoid liquid leak through.

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping.

5. Adding plug device can choose fixed mold or mechanical vacuum mold.

6. Machine body is made by 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

Technical Parameter

| Model | NP-Y2 | NP-Y4 |

| Filling nozzle | 2 | 4 |

| Capacity | 15-40 bottles/min | 30-80 bottles/min |

| Filling volume | 5-50ml | 5-50ml |

| Filling accuracy | ≥ 98% | ≥ 98% |

| Power supply | 1ph 220V, 50/60Hz | 1ph 220V, 50/60Hz |

| Power | 2.5 KW | 2.8 KW |

| Overall dimension | 1900 × 1800 ×1600mm | 2200 × 2100 × 1600mm |

| Net weight | 500kg | 650kg |

Warm tip

1. If out of filling volume range, we could customize for you.

2. If need higher capacity, pls reach us to customize the machine with more filling nozzles.

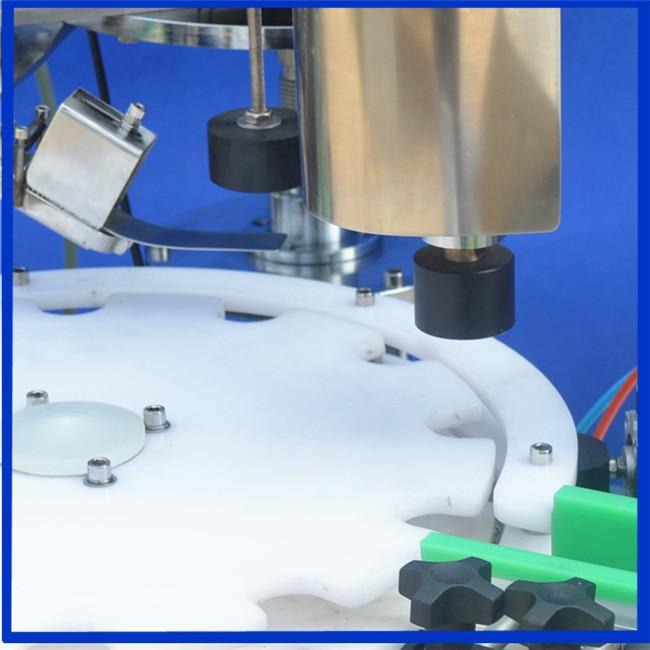

Machine Details

Peristaltic pump (achieve small volume liquid precise filling)

Automatic plug and cap feeder (SS-316)

Configuration List & Transaction Records

Color touch screen: Brand: Weinview / Taiwan

PLC controller: Brand: Mitsubishi / Japan

Frequency inverter: Brand: Delta / Taiwan

Intermediate relay: Brand: Omron / Japan

Motor: Brand: Siemens / Germany

Air cylinder: Brand: Air TAC / Taiwan

Whether you're expanding your operations or need to replace a particular piece of equipment, we have a wide selection of dependable, high performance packaging machinery to suit your requirements and keep production running smoothly and efficiently. There are transport conveyors to securely move materials and objects, scales and counters offering standard or precision measurements and several types of filling equipment for liquids, pastes, powders, and granules.

We service business handling food, pharmaceuticals, medical equipment, paper materials, electronics, machine parts, sports equipment, agricultural products, military equipment and much more.