Detailed Product Description

| Product Name: | Essential Oil Filling Machine | Voltage: | 220V/380V 50/60HZ |

|---|---|---|---|

| Power: | 3.0KW | Dimension(L*W*H): | 4600*4800*1600mm |

| Weight: | 1000kg | Filling Volume: | 2 To 120ml |

| Capacity: | 10 To 70 Bottles/min | Controller: | PLC From Mitsubishi |

| Pass Rate: | >=98% | Filling Accuracy: | ≤±1%(according To Product) |

| High Light: | eye drop filling machine, edible oil filling machine | ||

High Speed Essential Oil Filling Machine Suction / Anti - Drip Device Available

Whole filling line includes

1. Bottle feeder

2. Automatic filling and capping machine

3. Automatic vertical labeling machine

4. bottle collect machine.

Our eliquid/ essential oil small bottle Machines Can be Customized according to customers' bottle / requirement.

Application

This production line is mainly used for electronic cigarette oil, eye drop, essential oil, nail polish, eye shadow and other products fully automatic filling production.

Performance feature

1. Workflow: bottle unscrambling→bottle washing (optional)→filling→adding dropper/(adding plug, adding cap)→screw capping→self adhesive labeling→ribbon printing (optional)→shrink sleeve labeling (optional)→inkjet printing (optional)→bottle collecting (optional)→cartoning (optional).

2. This machine use a mechanical arm to screw caps, equipped with automatic sliding device, to prevent damage to the cap.

3. Peristaltic pump or piston pump measuring, accurate measurement, easy to control.

If use piston pump, when the filling volume difference is large, the corresponding pump body needs to be replaced.

If use Peristaltic pump, machine can adjust filling volume on the touch screen, and when bottle is not enough, machine will stop filling automatically, avoid waste.

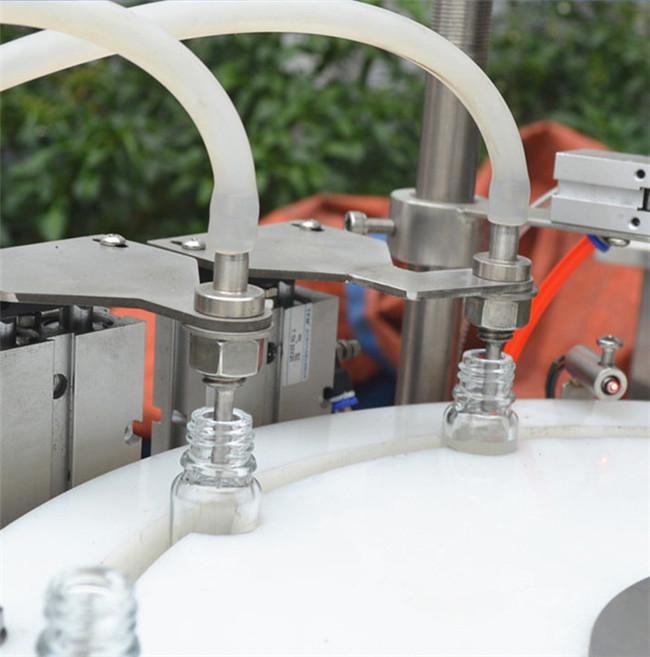

4. Filling system has suction / anti-drip device.

5. Color touch screen display, PLC control system, no bottle no filling (only peristaltic pump)/ no adding plug/ no capping.

6. The whole line is compact, high speed, high degree of automation, save the manpower cost.

7. Main electrical elements adopt foreign well-known brands.

8. Machine shell is made of 304 stainless steel, easy to clean, machine, meets GMP requirements.

Technical Parameter

| Model | NP-Y2/Y4 |

| Filling volumn | 5-120ml (othervolume Can be customized) |

| Filling Nozzles | 2, 4, nozzles Can be customized |

| Production capacity | 2 heads: 5-35 bottle /min, 4 heads: 10-70 bottle /min |

| Filling accuracy | ±1%(according to product) |

| Capping rate | ≥98%(according to product) |

| Power supply | 1ph, 220V 60/50Hz or 3ph.380V |

| Power | 3.0kW |

| Total dimension | 4600 * 3800 * 1600mmCan be customized |

More machine details

* Touch screen can choose to be Siemens or Wenview, all good brands

* 4 Filling Nozzles to fill 4 bottles at one time, fast speed

* 2 Adding Dropper/reducer/plug nozzle and 2 Screw Cap nozzles, rubber mould prevent damage to the caps. Fully automatic grade , save labor cost.

* Automatic Dropper vibrator feeder(Or caps vibrator feeder / plugs feeder.

FAQ

Q: Are you a factory or trading company?

A: NPACK Machinery is a factory who has rich experiences in food, drinks , medical and cosmetic industrials, we offer OEM services in the last over 10 years, and now we have our own brands and own designed machines for sale!

Q: How long need to ship the machines after order?

A: All machines can be ready and shipped in 15 or 30 days after order!

Q: What's the payment you prefer?

A: Our standard payment terms are T/T with 30% deposits and balanced before shipment.

Q: Why should you choose our packing and filling machine ?

A: We have been specialized in filling and packing machine for more then ten years, until now have exported mahcines to more than 30 countries

Q: Can you provide after-sale service ?

A:Yes ,sure.We have engineers available to service overseas .

Q: Can i visit your factory and send team for learning and inspect ?

A: Yes,sure.We will do our best to teaching you how to use the machine.

Q: What is our advantages?

A: 1.Competitive price

2. Excellent technical support

3. Best service